|

This is the second industrial project demonstration, to review the first demo, please use the link: what-we-do-in-china-teamwork-through-evo-jmgreen.html

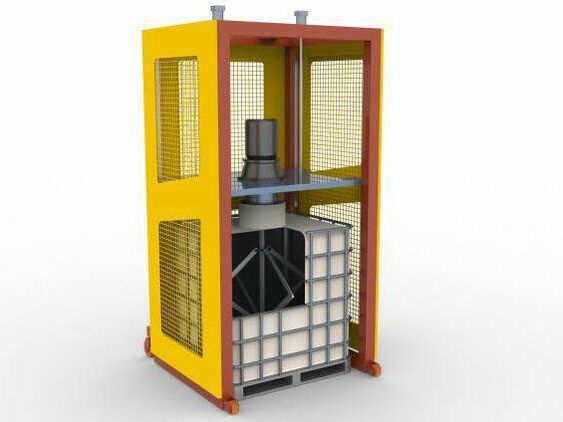

This facility practices one time feeding, where the bioconversion rack only receives one time of feed at the beginning and will be sit in the bioconversion room for the remaining time. During the bioconversion period, many heat and ammonia are being generated, thereafter the central air conditioning system along with small air circulation units, and ammonia scrubber are necessary. The sifting system is comprised with a vacuum transporter and a frass separator. The vacuum transporter moves the larvae and frass content from the bioconversion pan into the storage vessel, then being elevated into the frass separator.

This facility at its full capacity produces 1300KG dried product a day. Author: Spring Yang

37 Comments

David Henderson

1/23/2019 03:37:57 am

Fabulous!

Reply

Alejandro

2/7/2019 07:25:50 am

Great post, thanks for sharing.

Reply

Spring

2/8/2019 02:51:29 am

You are right, that prevents larvae from escaping

Reply

Adam Micyus

3/21/2019 12:58:30 pm

It is probably wheat bran. It is very dry and absorbs excess moisture and becomes feed as well. Soldier Fly Larvae find dry environments to be hostile and avoid them. So the barrier provides a twofold purpose, Absorbing excess water to prevent larvae drowning and to prevent larvae escape by killing by desiccation or providing a hostile environment they will actively avoid.

Reply

Matt Sutton-Vermeulen

2/14/2019 01:51:25 pm

Very creative thought process using the fermentation process to kill pathogens and stabilize at the same time. What do you do with the offtake from the ammonia scrubber?

Reply

Spring

2/14/2019 06:25:01 pm

We are still looking into opportunities for the scrubber offtake, though looks like using it as agricultural fertilizer is the easiest way.

Reply

Marc

12/1/2019 09:22:03 pm

There is the NH3 ammonia as fuel effort in the US of A. Their idea is to take stranded electric and make a liquid fuel of Ammonia.

Jerry

5/16/2019 04:59:30 am

Incredible engineering work.

Reply

Spring

5/16/2019 05:32:36 am

Our fermentation process inhibits the rotting and uncontrolled molding, and in this feeding system we want to keep the undigested feed at anaerobic condition to prevent molding. Our pan also help preventing these problems

Reply

Jerry

5/16/2019 07:15:15 am

Amazing 👌

rahul

12/26/2021 09:03:18 am

we read the large pans recieve one feeding and larves are harvested on the 8th day. can we get to know how much kgs of feed is put in per large pan ?

Max

6/28/2019 05:21:07 am

Amazing. Can you help me to contact company build automatic feeding tower . I want to know something about that. Thank you so much

Reply

2/8/2022 12:35:17 am

I am interested about this matchine setup. I am planning to produce 500 kg lerve per day.Could you please give me any idea about the match set up? Thanking you.

Reply

Alessio

8/17/2019 02:11:55 pm

Amazing post, thanks for writing it. One question, you say the plant produces 1300KG of dried larvae per day, but at the beginning of the post you write the plan is treating 100 Tonnes per day of organic waste. I thought you’d get much more dried larvae from 100 Tonnes, maybe I am missing something, could you help me understand, thanks.

Reply

Spring

8/17/2019 11:33:20 pm

Hi Alessio, thanks for your comment. The site collects 100 tons a day, though 80% of them are free flowing liquid, and those are sent to biogas reactor. Hope this helps.

Reply

Dale Annison

12/30/2019 11:07:21 pm

What strains of probiotics is to promote fermentation, and do you culture these as a part of the production cycle?

Reply

2/29/2020 07:20:17 am

Hello. Please tell me how much does such equipment cost? Is it possible to buy it?

Reply

3/27/2020 08:42:49 pm

We are Toronto based start-up consultants.

Reply

rahul

12/26/2021 10:19:43 pm

hello sulaiman sir

Reply

Eslam Abdallah

7/27/2020 05:31:03 pm

Seperat technology?

Reply

Izzah

9/20/2020 06:05:58 am

How much is the larvae feed being sold?

Reply

David

11/20/2020 03:32:21 pm

The truth it's inspiring. Currently am in Uganda and am trying to set up facility that can supply my poultry farm. I had reached a level of collecting 210g of eggs in a week but just because we are in the rainy season, am getting 50g a week.

Reply

Omega

11/16/2022 03:00:45 pm

Work on your humidity and temperature

Reply

Gian Carlo Marcanti

12/7/2020 09:34:42 pm

Congratulations for your excellent blog. A couple of simple questions: what is the average weight of fresh harvested larvae? and what is that of the dried larvae?

Reply

3/25/2021 03:42:26 am

I would like to find out is there other methods other than trays to bioconvert

Reply

9/3/2021 10:44:08 am

Hi ! Can you tell me which type of probiotics are you using for fermentation ? can you sell it ?

Reply

8/4/2022 12:55:55 pm

Your article is fascinating. , you have enriched your craft delightfully. It rouses individuals a ton. In the event that the subject is acceptable, at that point it is likewise enjoyable to peruse and this is the thing that individuals need these days, your post is truly intriguing. Enlivened by you, I also figure I ought to compose an article on a great subject.

Reply

10/27/2022 11:31:40 pm

Water security has become a deep concern across Australia, as a result of inadequate dams, expanding population, and the effects of global warming, culminating in frequent catastrophic droughts.

Reply

12/17/2022 06:00:50 pm

I am interested in the machines though for processing 1-2 tonnes of waste daily please advise

Reply

9/28/2023 05:50:08 am

Please give us contact details for us to get some information.

Reply

I am seeking expert consulting services for expanding our Black Soldier Fly production. We need guidance on facility design, regulatory compliance, production optimization, and marketing.

Reply

Ken Mugane

11/28/2023 07:24:38 am

How much would the set-up cost of a similar plant be? Any links to a manufacturer that can set it up in Nairobi Kenya?

Reply

Lionel Weich

1/14/2024 11:35:05 pm

Please quote on a 20 ton waste plant per day. Best regards. Lionel

Reply

4/27/2024 06:12:24 am

Is a very informative comment, you have some things in it that have touched the mind, I want to thank you very much

Reply

4/27/2024 08:54:04 am

Thank you very much for writing a great post. If there is anything in my life that I think is very important and I should understand it, I always try to understand it and I have seen your post. Saw this and liked this post a lot, so I am complimenting your post thoughtfully.

Reply

Leave a Reply. |

AuthorIndividuals with over 25 years research experience with the black soldier fly. We are passionate about the science behind the black soldier fly and its ability to convert waste to protein. Get Notified Here

Archives

September 2022

Categories

All

Install an RSS app to get notified from us when a new post is up!

|

ServicesSupport |

About |

RSS Feed

RSS Feed